Food Bacteria Count System

Featured in "Standard Methods of Analysis in Food Safety Regulation"

AOAC Research Institute

Performance Tested MethodsSM License Number 040801/120801

Performance Tested MethodsSM License Number 040801/120801

Food Sanitation Inspection Guidelines, Microorganisms Edition 2018 (included)

DOX is a "reliable" and "accurate" bacterial testing system that has been listed as a rapid and easy method in the Microorganisms Edition of the Food Sanitation Inspection Guidelines since 2015.

Count food bacteria in-house, quickly and easily!

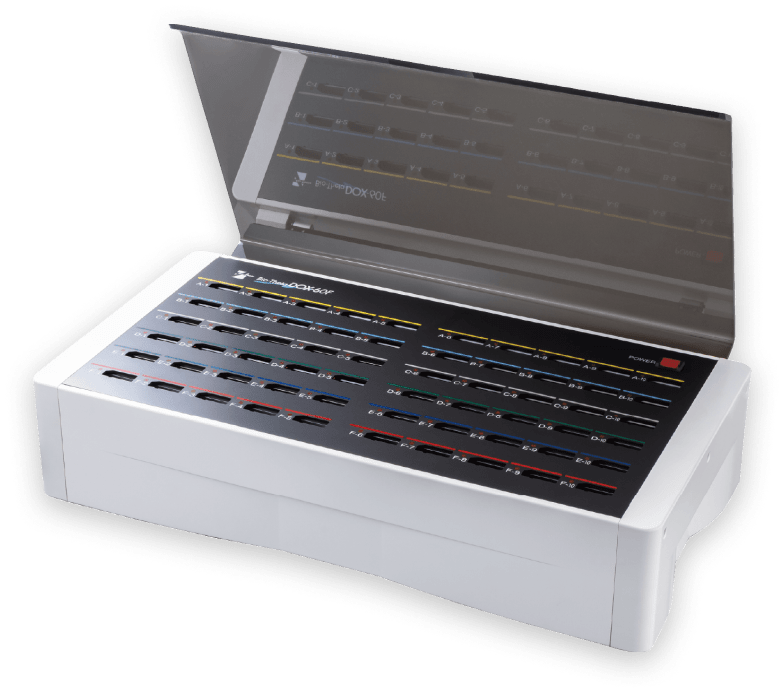

DOX-30F

DOX-60F